Bubble Troubles

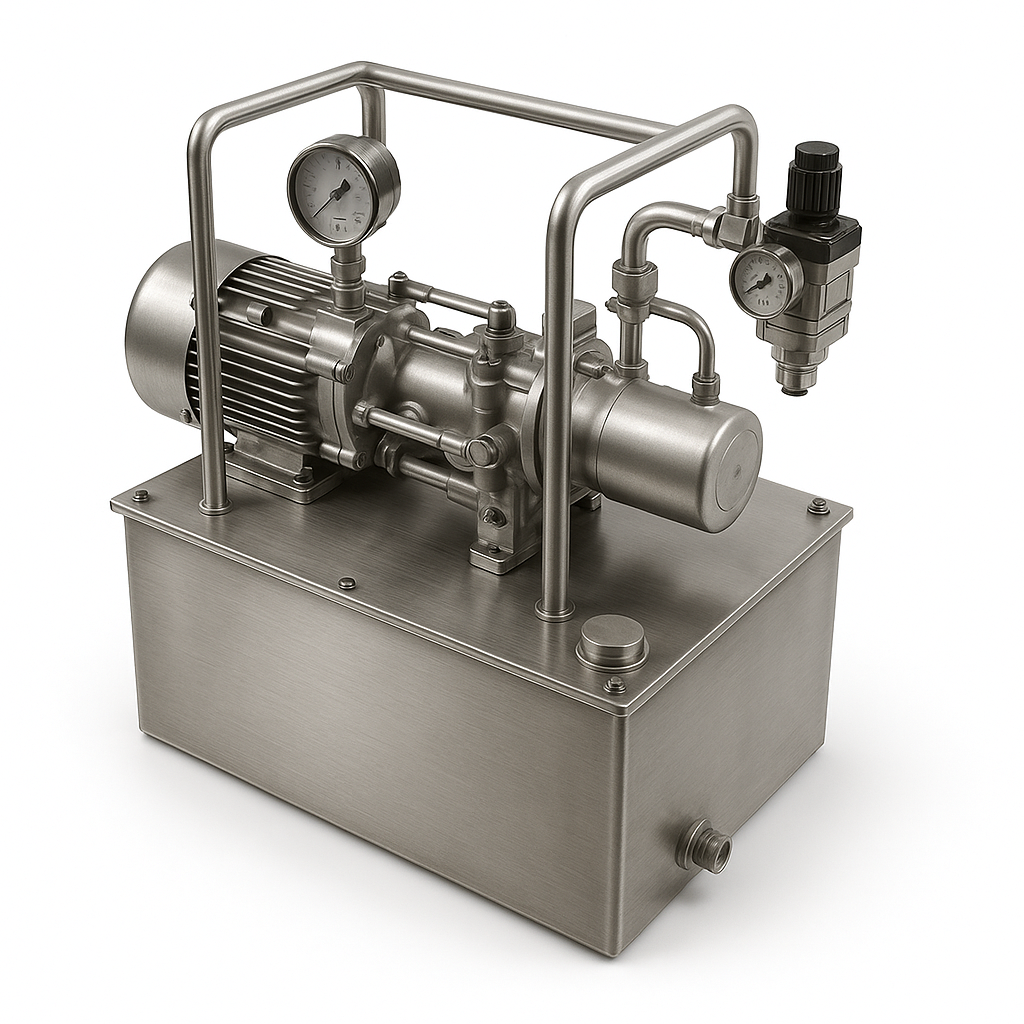

Hydraulic System

Coating System

Beverage & Pharma

Critical Issues and Risks of Bubbles in Hydraulic Systems

Problems due to air bubbles such as product defects and measurement problems vary widely depending on the type of liquid, but lets look at a hydraulic system as a typical example.

Air Trap

Dispersed bubbles dissolve in oil when pressurized by a pump, but they will precipitate again as bubbles when the pressure drops. From the above, when the hydraulic system is stopped and left unattended, the deposited bubbles will rise and collect at the highest part of the liquid. This can cause unexpected troubles such as cylinder malfunction, breathing, and pressure fluctuations. Known examples of troubles include sudden operation of hydraulic cylinders and combustion deterioration of cylinder packings.

Oil Temperature Rise

If the bubbles are momentarily pressurized by a pump, the temperature will rise rapidly. The approximate value can be easily calculated assuming that the gas does not dissolve in oil and is adiabatically compressed. For example, when a bubble at 35℃ is pressurized to 3.5MPa, it reaches 580℃ in calculation. When the bubbles become hot, the oil around the bubbles burns, causing the oil temperature to rise. Since air does not easily transfer heat, inclusion of air bubbles in oil lowers the heat transfer coefficient and reduces cooling performance. The combination of these factors can cause air bubbles to affect the cooler capacity.

Oxidative Deterioration of Oil

Air bubbles reduce the oil film strength, cause metal contact inside the equipment, and accelerate wear. It shortens the life of hydraulic equipment.

Feel free to ask for consultation or quotation